FOR generations, there was barely a family in Poole that did not have some connection with the Hamworthy group of companies.

It started on the Quay but later moved to a massive factory site at Fleets Corner – employing around 3,000 staff worldwide at its peak.

The businesses that made up the Hamworthy group spent much of last year assembling photographs, documents and personal memories to mark the centenary of the original company’s founding. A selection of that material is now on display at Poole Museum.

Hamworthy Engineering might not have existed if it had not been for the Mexican revolution that began in 1910.

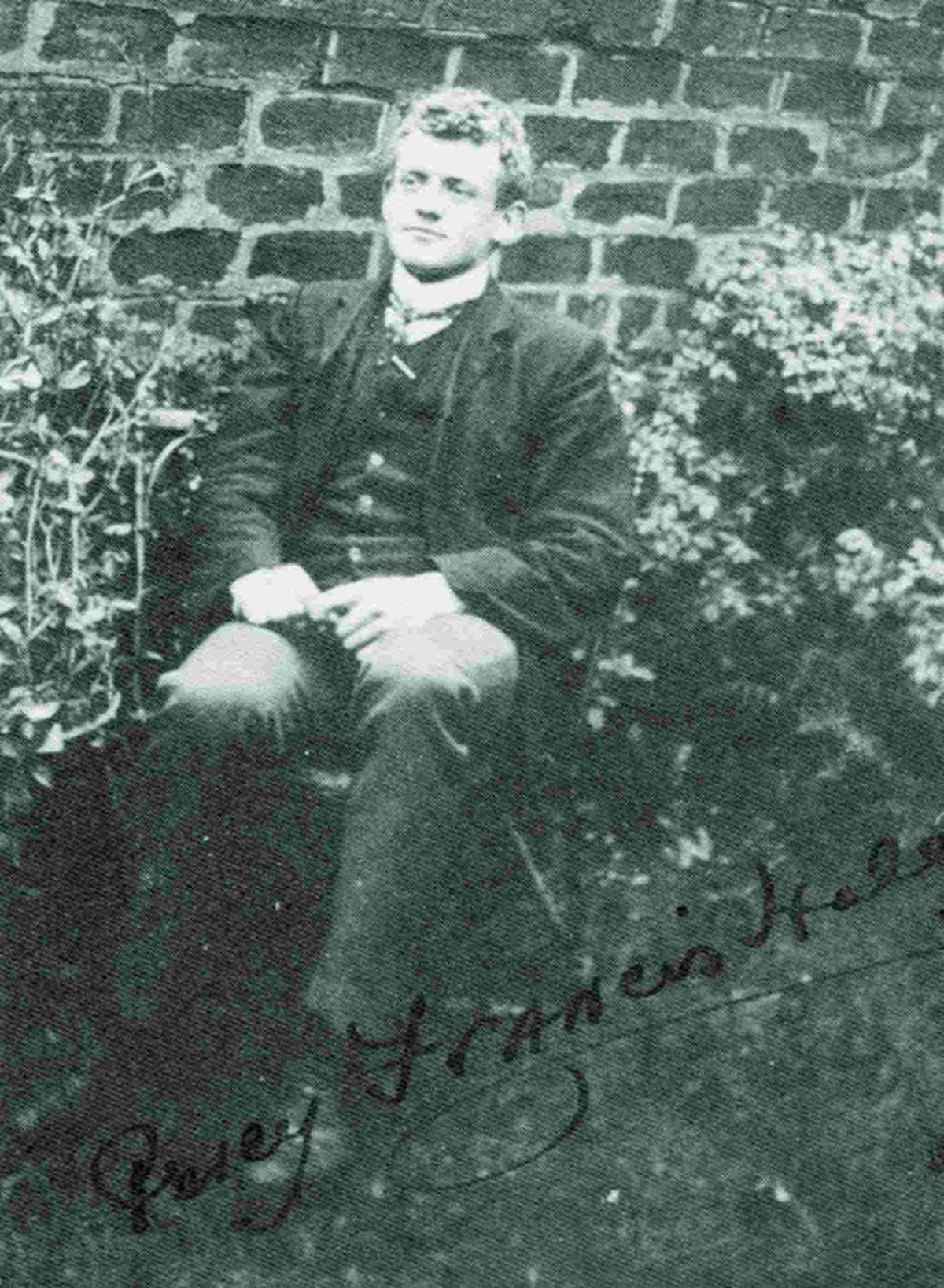

That uprising persuaded Percy Francis Hall, an oil exploration engineer travelling in Mexico, to return to England.

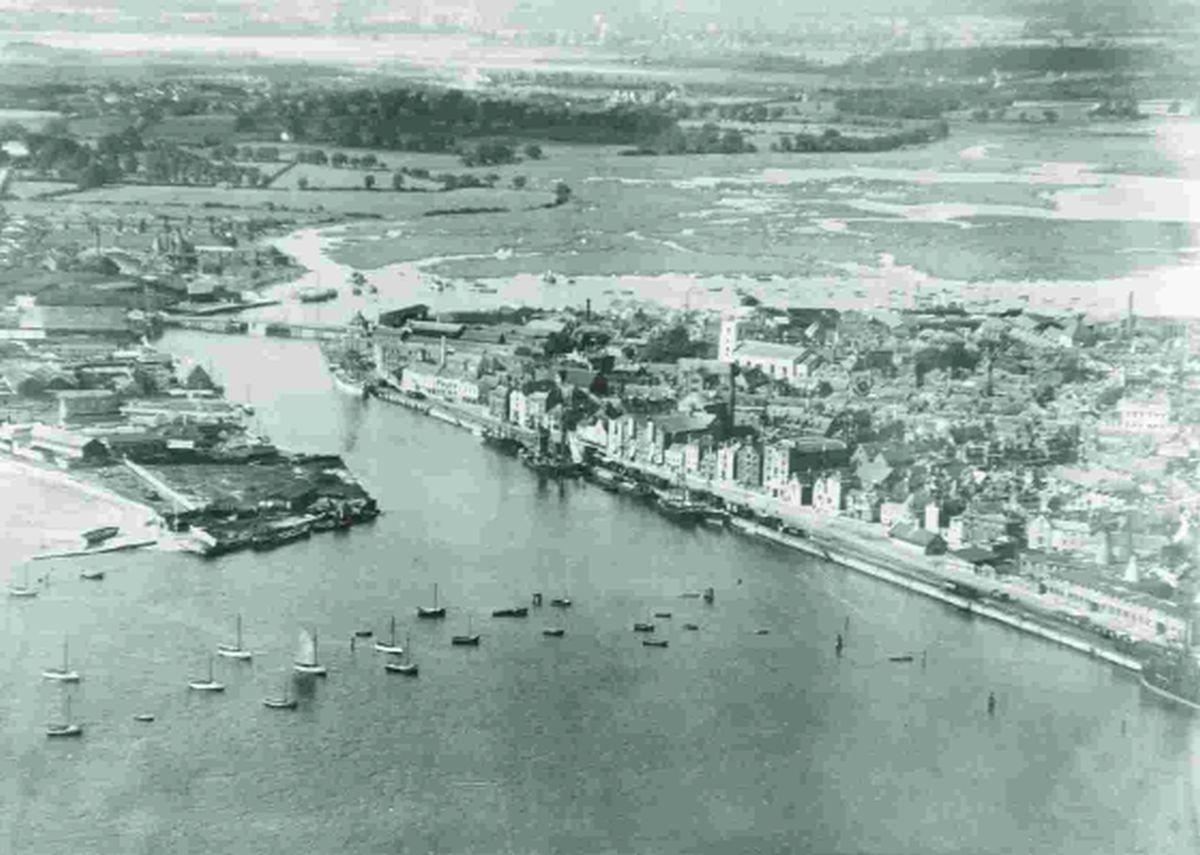

He bought an acre of land on what is now Poole’s New Quay Road and established Halls Engineering Company, specialising in marine engines and boat repair, initially with six employees.

Percy Hall was joined in 1914 by his brother Sidney and together they incorporated the business as Hamworthy Engineering.

With the outbreak of World War One, the company grew rapidly. It was one of the first businesses to be given a Class A Approval Certificate from the Admiralty, meaning its products could be accepted without further quality control checks. The company worked day and night fulfilling contracts.

By 1915, it was employing 150 men and women.

Percy Hall wrote to his future wife that year: “We have so many Admiralty contracts that we do not know what to do and are now extending the works to cope with some of the work.

“All the time we are preparing for after the war and trying to make ourselves into an absolutely up to date firm ready to compete with anyone else in the country.”

When the war was over, the Hall brothers were keen to keep ahead of other producers of pumps and compressors. They set up a foundry a mile from the factory, providing high quality castings.

Hamworthy’s engines were initially used locally by fishing and other commercial craft, for powering deck cranes and winches. But they served other purposes too, from generating power to powering agricultural machinery.

With a national power network still some way off, Hamworthy did a good trade in selling small-scale power generation kits to large houses rural Dorset.

In the Depression, the foundry was used for anything that could be cast or repaired.

The foundry provided Poole with lampposts and manhole covers bearing the town’s Dolphin emblem.

But the business suffered a huge blow in June 1936, when fire destroyed the main pattern shop. It meant the end of production for Hamworthy engines.

During the Second World War, Hamworthy’s pumps and compressors were used in anti-aircraft guns and in torpedo boats and assault ships.

Hamworthy produced a lightweight compressor for a midget submarine, which crippled the German battleship Tirpitz.

By the 1950s, the company was outgrowing its premises, and opened offices in Liverpool, Glasgow, Aberdeen and Grimsby, as well as reopening the London office, which had closed during the Blitz.

It built a new factory at Fleets Corner, while the Quay premises were turned over to the pump and compressor division.

Powell Duffryn Ltd acquired Hamworthy Engineering and a half-share of Hamworthy Hydraulics in 1962.

The Fleets Corner operation was expanding and in 1968, the Lord Lieutenant of Dorset laid the foundations of a five-storey office block. He also presented the pumps and compressors division with the Queen’s Award to Industry for its export achievements. The company finally left the Quay, moving the pumps and compressors division to Fleets Corner.

A transmissions division was established in 1971. Another factory was built at Fleets Corner and by 1979, it covered 85,000sq ft.

By the end of the 1980s, the group had 3,000 staff across the world and a turnover of £110million.

Numbers dropped after the David Brown Group bought Hamworthy Hydraulics and Hamworthy Transmissions in the 1990s, moving production of transmission systems to Huddersfield and later the hydraulics division to Turkey.

The buying and selling of parts of the group over the following years is a complicated series of events.

The Wartsila Corporation of Finland bought Hamworthy Engineering and its Fleets Corner base provides technology to ships and offshore units all over the world. Other operations still on the site are Hamworthy Heating and the combustion business, now US-owned as John Zink Hamworthy.

Despite the internationalisation of the current businesses, many families have still had members there for generations.

Dave Allbrighton, after-sales adviser at Wartsila Water Systems, said the 21 Club – for current and retired employees with 21 years’ or more service – had 500 members.

“My father worked there and I joined. Other relations were working there as well – there’s always somebody,” he said.

Richard Price, sales director for Hamworthy Combustions spoke at a reception to mark the launch of the Hamworthy display at Poole Museum.

“Everybody here is very proud to be part of Hamworthy over many years of service,” he said.

“Most people know somebody that’s worked at Hamworthy. My father was here 49 years. There are many other engineering people that have been through Hamworthy and it’s great to see some recognition locally.”

Michael Spender, the Borough of Poole’s museum and arts manager, pointed out that Hamworthy was once Poole’s biggest employer.

“It’s great to have this display from this really important Poole company that means so much going back over 100 years to the people of Poole,” he said.

Memories from former staff

Many former staff shared their memories of Hamworthy during research for the company’s centenary.

John Galton of Oakdale, who worked in the transmission department, said: “My dad also worked at Hamworthy and he was there for 30 years working in the pumps and compressors department which was actually the last to leave the quay in the early ’60s.”

John was involved in moving the moving of the Hamworthy club from Fleetsbridge (where Tesco now stands) to Magna Road.

“One of my fondest memories was the opening of the new social club – we had two marquees up, one with Kenny Ball and the other with Acker Bilk. It was an absolutely fabulous night.”

Judy Day of Broadstone told how her father Walt left school to work as an apprentice in Hamworthy Engineering’s drawing office in 1916.

“He was working 63 hours for four shillings – 6am to 6pm six days a week,” she said. “He then moved to the engineering shop earning 12 shillings. He eventually progressed into the office for more pay and fewer hours. After his journey to work costing threepence a week, then giving money to his mother, there was really not much left over.”

He was also part of the apprentices’ football team and could name every player in the picture on this spread.

He was laid off during the national slump in 1921.

Robert Case of Bournemouth was with Hamworthy from 1979-1997, working on compressor design, and was also involved on the union committee.

“I remember us having three different finishing times to prevent traffic leaving the site – it was a good idea but this did lead to confusion trying to remember which day of the week it was,” he said.

“Working at Hamworthy was a happy working environment for all employees and I have many good memories of working here and am still in touch with some of my colleagues from Hamworthy now.”

Margret Kiff of Wimborne went to work in Hamworthy’s typing pool aged 17 in 1964. She was promoted to work for the sales manager and followed him through the company.

“I left Hamworthy in 1972 because I was pregnant but I got a lot of support within the office during my pregnancy. I always got cravings for Coca-Cola and had to get it from the vending machine where all the men worked, so every morning I would waddle down to buy my Coke and never once did I buy it for myself – one of the men would always buy it for me,” she said.

She added: “I was so lucky working for Hamworthy. The team there were like a family. When I joined in 1964 they were known as best employers in Poole. All employees were treated with the utmost respect and we were well paid for what we did.”

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here