COMPANIES have joined the University of Bradford to get behind the effort to produce PPE during the Covid-19 epidemic.

Engineers from the University have started the mass production of face shields with orders for 15,000 already.

The project is being carried out at the Faculty of Engineering & Informatics in partnership with two local companies, Leeds-based additive manufacturer ActiveCell Technologies and Teconnex from Keighley.

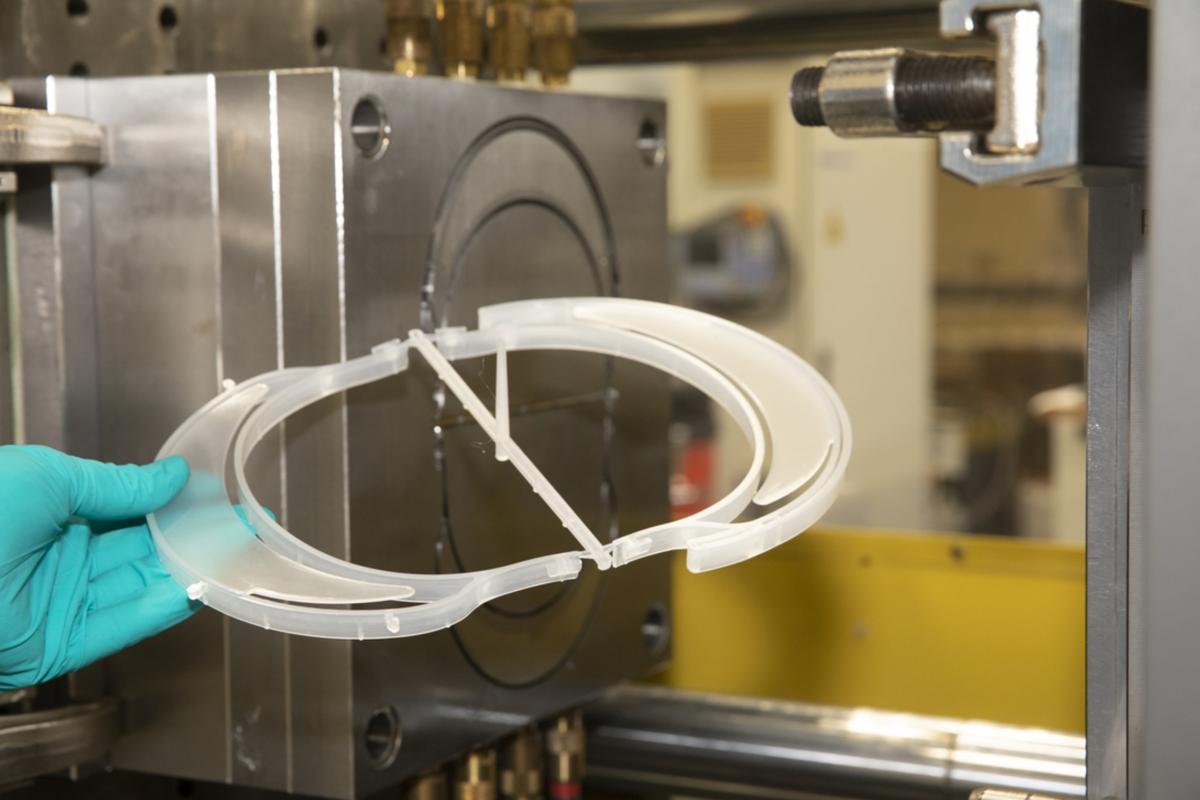

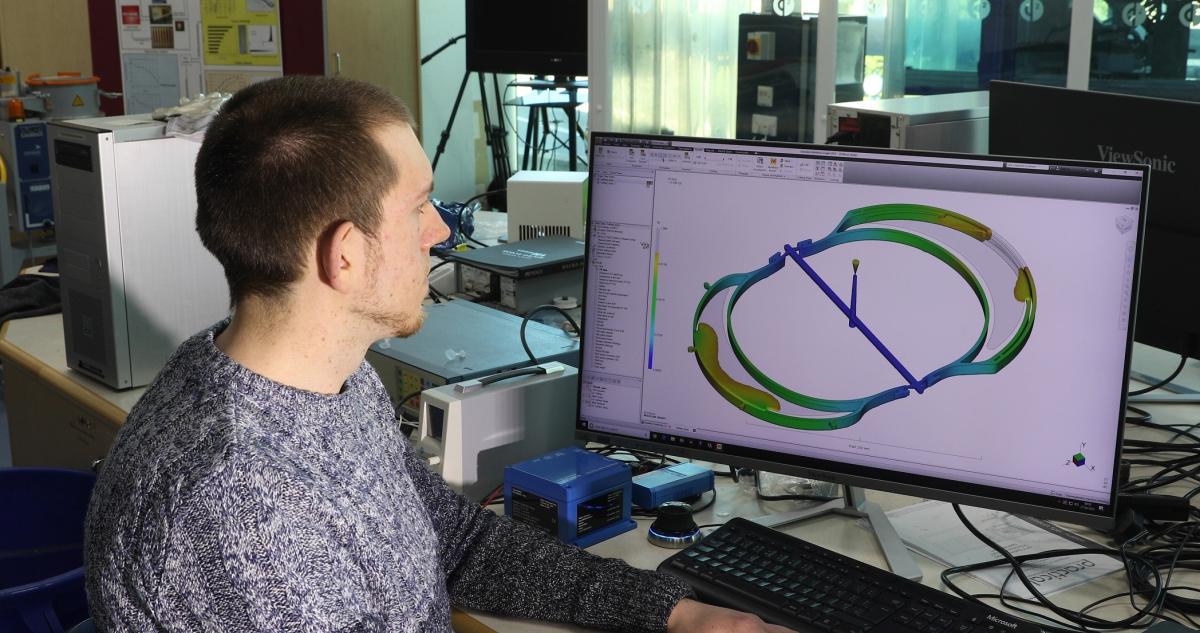

Academics are using hi-tech 3D printing and polymer injection moulding machines, capable of turning out thousands of pieces of protective face shield components a day.

Mould sets ordered from Germany and designed and machined in Bradford mean the university has the capacity to produce in excess of 5,000 units per day if needed.

Head of the Department of Mechanical and Energy Systems Engineering, Professor Tim Gough said the work was in response to an order for the equipment from the NHS, adding it had taken a number of weeks to get to the point of manufacture.

“These are not the facemasks which you now see many people wearing in public but face shields, which have a clear plastic visor.

"A lot of transmission [of coronavirus] is coming from patient coughing and that can infect the carer through respiratory transmission. We are manufacturing headbands and headpieces to go around the head, which you can then attach a visor to.

“It has taken us some time to get to this stage because everything has to comply with strict cleanliness standards, so we have had to deep clean everything, even the injection screws and screw barrels, to create a ‘clean room environment’.”

He added the initial NHS order was for 10,000 units, with a further 5,000 ordered by Bradford Council.

Prof Gough, who has worked at the university for 23 years and has ongoing projects with a number of companies, including vacuum manufacturer Dyson, is one of a team of six who are carrying out the work on campus.

They are using 3D printers to create prototypes and then polymer injection moulding machines to create products. The headbands have even been made so that acetate sheets used in overhead projectors can be attached as visors as a last resort.

They are also working on two other designs, one called an ‘ear saver’ to stop chafing caused by prolonged mask wearing in a medical setting and an alternative face shield design for use in care homes.

He added: “In practical terms, this is what we do. Yes, there’s a level of complexity to it but we are used to making products and we have done this kind of thing for years.”

Tim is part of a six-strong team, which also includes Professor of Precision Manufacturing Ben Whiteside, research engineer Michael Hebda, technical services manager David Barker and engineers John Hornby and Glen Thompson.

Prof Whiteside, who leads the Polymer Micro and Nano Technology Research Centre said: “The challenge has been to review the problem, finalise designs and manufacture tooling at time scales that are far quicker than industry norms, while also offering significant benefits over existing solutions for our NHS staff.”

Teconnex production engineer Paul Shepherd, which is helping with manufacture of the headbands and laser-cutting of visors, said: “It’s important to help out at this time.

"We have also said we will help provide local care homes if we can.”

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules here